Paper has a wide range of uses, from textbooks to tea bags, toilet paper to decorative wallpaper. This versatile material has countless uses. And for a short period of time in the late 19th century, it was used to make train wheels.

It makes sense that all load-bearing structural elements should be made of durable materials. So how did the idea of making paper wheels come about?

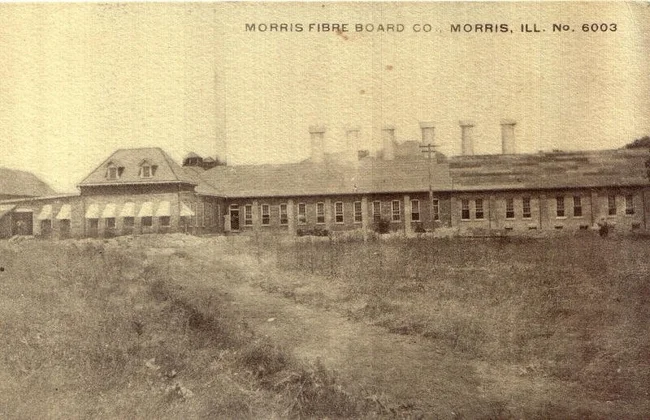

Morris Fibre Board Co, Morris, Illinois

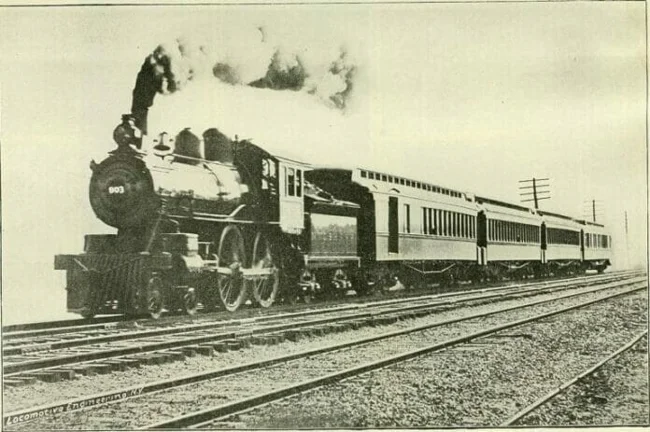

Until the 1870s, railroad car wheels were mostly made of cast iron. Some were compound with wrought iron rims and wooden driving centers. Cast iron wheels transferred all the imperfections of the track to the car, making for a noisy and uncomfortable ride. As passenger cars grew heavier and trains ran faster, the ride became more uncomfortable. Plus, passengers felt unsure because cast iron wheels were brittle.

Trains in the 19th century were pretty uncomfortable - noise and vibration were a real problem

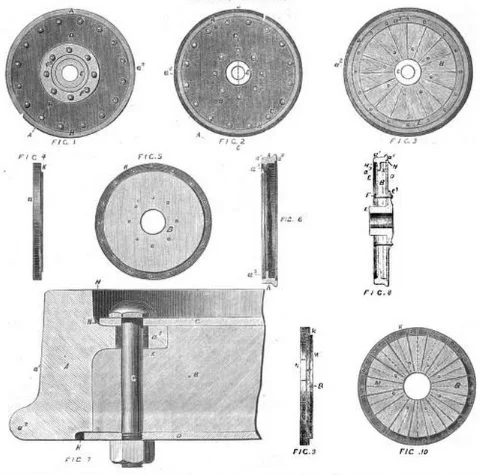

To dampen the vibrations and make the ride more enjoyable, locomotive engineer Richard N. Allen came up with a solution in 1869. Allen came up with the paper wheel. It wasn't exactly paper, but consisted of a metal rim, a cast iron hub, and two round iron plates that contained an inner core of hundreds of sheets of straw. They were glued together to create a tight, monolithic structure that could support a lot of weight.

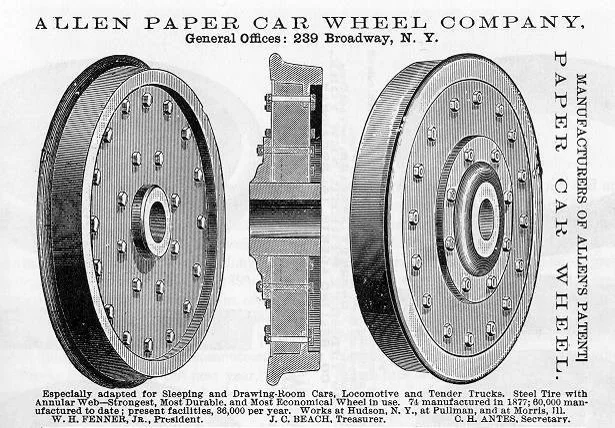

Allen first tested the wheels on the Rutland and Burlington Railroad, and when he was satisfied with the results, he started a business to manufacture car wheels. The Allen Paper Car Wheel Works was originally located in Morris, Illinois, and its main customer was the Pullman Palace Car Company of Chicago.

The Pullman Company was known for its plush dining cars and sleeping cars with carpets, draperies, and overstuffed chairs, and the timing of Allen's invention coincided perfectly with the growth and development of Pullman. The first order for one hundred wheels was placed in 1871. They eventually became standard equipment on all Pullman cars. The volume of Pullman orders forced Allen to open a factory in Pullman.

Pullman car, second half of the 19th century

The company's main factory was in Hudson, New York, where Allen employed thirty people who made about ten wheels a day. The cores were made from sheets of paper that were glued together in batches of ten and pressed. The pressed disks were then steam-dried for several days. The process was repeated over and over until the paper cores were about six inches thick.

Allen Wheels

By 1881, the Allen Paper Car Wheel Co. had shops in New York and Chicago, but kept its plant in Morris. Each shop employed about 80 people and produced more than 24 wheels a day. The company produced and sold thousands of items each year. By 1893, it is estimated that 115,000 of these wheels were in use on American railroads.

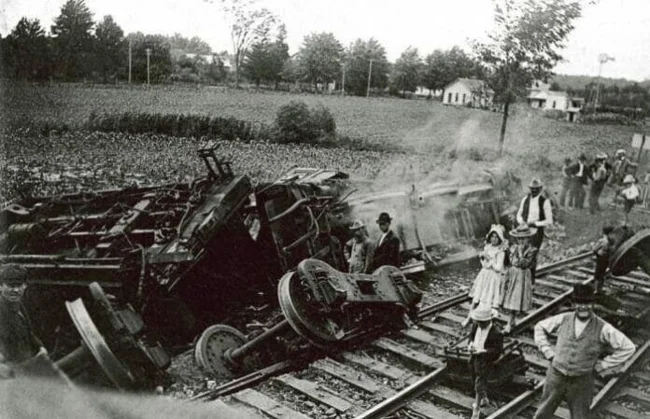

1895 Train Crash - Paper Wheels Believed to Be Caused

The end of paper wheels came at the turn of the century, when the design of carriages, their weight and brakes changed, especially with the transition from wooden to steel carriages. They became heavier and put much greater stress on the wheels. In 1915, the Interstate Commerce Commission recognized paper wheels as unsafe and gradually phased them out of service. Not only did paper wheels disappear from use, but also all composite wheels, which replaced steel structures.

"Paper" wheel

Add your comment

You might be interested in: