Giant ancient elevator wheels. Who created them and why (5 photos)

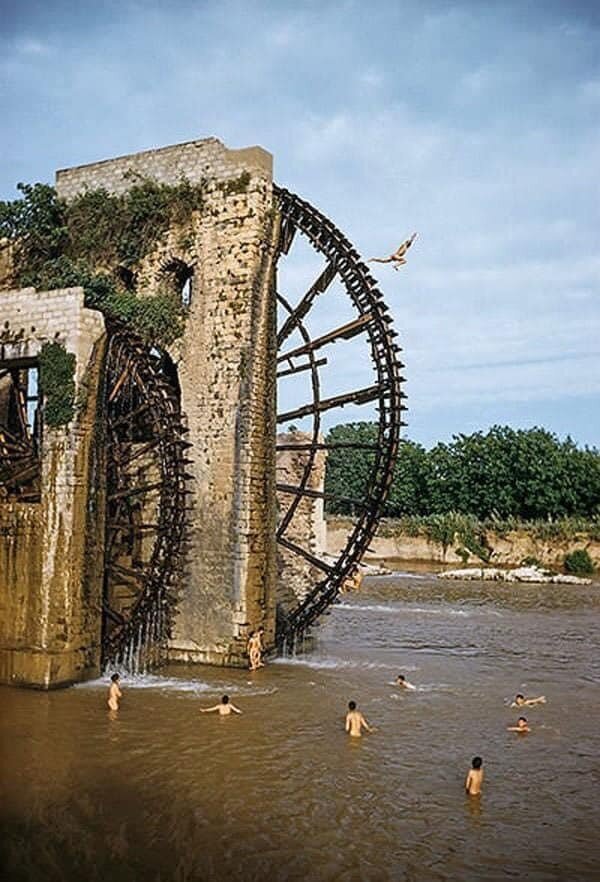

In Syria you can now see giant wheels located along the Orontes River. They are wooden, very ancient, but still standing.

It is the oldest surviving hydraulic system. The largest wheels reach 21 meters in height - that is, the size of a seven-story building.

They appeared in the 300s AD. The first wheels were most likely built by the Romans. Subsequent wheels were similar in design, but appeared much later - in the 7th-9th centuries. Most likely, the Arabs who conquered these areas appreciated the benefits of the devices and began to create similar designs.

According to written sources, new wheels were actively being built until at least the 13th century AD. Further, new wheels were not assembled, but all existing ones were restored. In the Middle Ages, 30 wheels functioned here, 17 of them have survived to this day.

The history of such structures goes back to ancient times. They are believed to have been invented in Ancient Greece or Mesopotamia and later perfected by the Romans. However, the oldest surviving wheels in Ham date from the 13th century, when the city was an important center of agriculture and trade.

The main function of the elevator is to lift water from the river to irrigate nearby fields and gardens. The wheels are driven by the force of the river's current, and special buckets attached to the rim of the wheel scoop up water and lift it to the top. The water is then poured into aqueducts that distribute it across the fields. Each bucket scooped up from 4 to 12 liters of water. And the total water supply for one wheel ranged from 50 to 200 thousand liters per hour.

The Orontes River has high banks and no slope. Therefore, such wheels were the most effective way for the Middle Ages and Antiquity to obtain water for irrigation.

Of course, wooden parts are short-lived. During active work, all wooden wheel parts were replaced approximately once every 15 years. For this purpose, there were separate families here who passed on skills from generation to generation.

Norias began to be abandoned only in the 50s of the 20th century. They began to be replaced by new irrigation pumps powered by gasoline and diesel engines.

Thoughtful materials and design

The parts are made from different types of wood. Massive axles and bearings were made of walnut wood. For others, oak, pine and poplar were used.

Walnut wood was perfect for important parts

Engineers were well aware of the differences between types of wood. Walnut was chosen for axles and bearings due to several qualities:

Very durable and hard wood. Parts must withstand significant loads and wear.

Stable sizes. Walnut wood has relatively low hygroscopicity. That is, it contracts and expands less strongly under the influence of moisture and temperature.

Rot resistant. Walnut wood contains natural tannins and oils, which significantly increase resistance to rot and decay.

Self-lubricating. Natural oils act as a natural lubricant, reducing friction between moving parts. Oak, pine, and poplar were used for other elevator parts, such as paddles, buckets, and structural members, due to their wide availability, relative strength, and ease of processing.