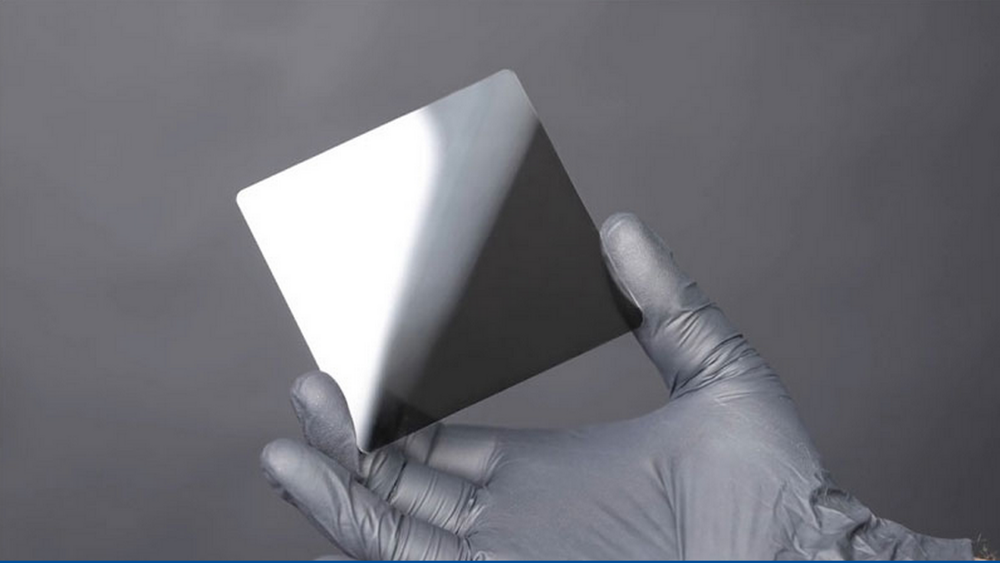

Cerabyte showed the operation of an “indestructible” data storage system on ceramic-coated glass (3 photos + 1 video)

The young German company Cerabyte showed a working prototype of a data storage system on ceramic-coated glass, and also demonstrated the process of recording information. Up to 100 PB can be recorded on each platter with sides of a few centimeters.

Image source: Cerabyte

This can become a more reliable and economical alternative to tape and optical libraries, since glass and ceramics are not afraid of fire, water, radiation, magnetic fields and other influences.

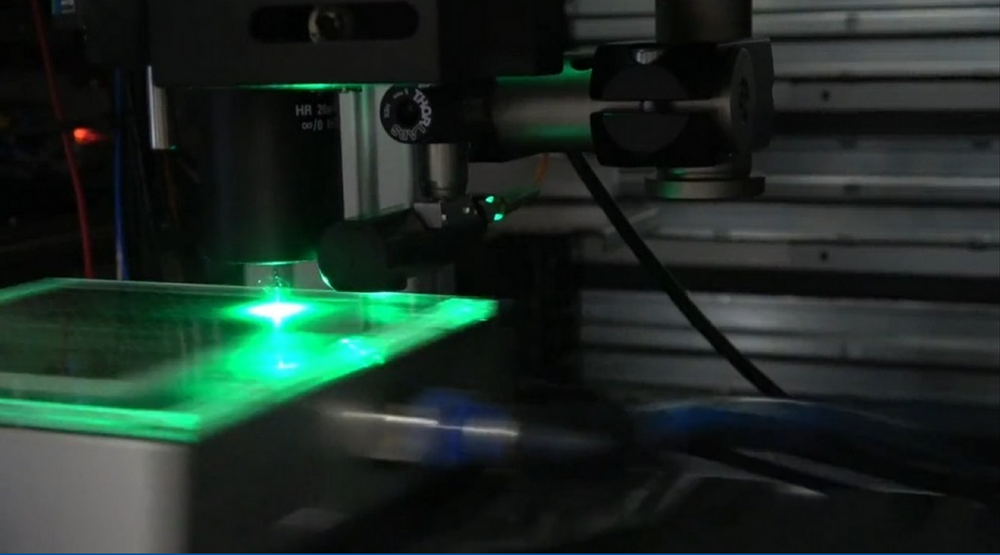

The announcement of a glass recording system with a ceramic layer took place in September of this year. Now the company has shown how this system works. The video shows how the glass plate is removed from the cartridge, placed on the recording and reading pad, as well as the recording process.

Screenshot of laser processing

Recording takes place in two passes. A femtosecond laser writes a line of information in one pass, and in a reverse pass, a special camera reads what was recorded and, thereby, verifies the recording. In case of reading, the camera works in both directions, which makes this operation twice as fast as recording.

Subsequently, the recorded record is stored in a cartridge in a robotic library and storage does not require energy. Records are recorded once and for all and do not require special procedures to maintain data integrity, which, for example, is required for tape drives.

The ceramic layer on Cerabyte glass plates is between 50 and 100 atoms thick.

Ceramics are applied to both surfaces of the plate. During recording, the laser burns holes into the layer, encoding the data in binary code (whether there are holes or not). The data recording format is ordinary QR codes, which makes the solution compatible with common file systems and operating environments, as well as programs. But each group of codes is so small that it cannot be seen with the ordinary eye.

QR template data blocks written with a ceramic layer on Cerabyte glass media

Each laser-made hole in the ceramic is 100 nm wide. In the future, the developers promise to reduce it to 3 nm, which will require using something more complex than conventional cameras for reading. For example, electron microscopy. Over time, this will not be difficult if Cerabyte's idea finds support among industrialists. For now, the company is only looking for people willing to implement its development.