Making a bed with your own hands (30 photos)

It all started when the bed ended. I mean, it's completely out of order. It's scary to think - she was only five years younger than me...

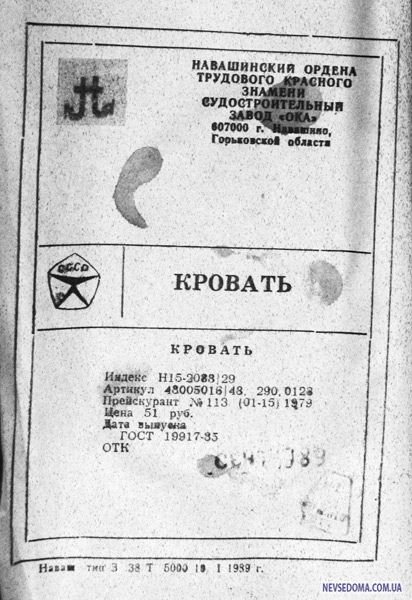

This piece of furniture was once built (another word, perhaps not appropriate here :-)) all the way at the Navashinsky shipbuilding plant "Oka".

The design was, to put it mildly, not very successful, assembled from “polished” chipboards, classic for that time. It's amazing that she lasted that long at all. The shipbuilders in Navashino apparently laid in a decent safety margin. But, however, the time has come for "H".

Even before the New Year, I decided to slightly update the furniture in my room. To begin with, a wardrobe made of laminated chipboard was designed and assembled. I had my first experience with this material a year ago - then I made a small bookshelf. But there were no problems with the cabinet, this “large furniture form” - it turned out quite reliable and beautiful.

And I decided - I can take on the bed. The first thought was simply to simply repeat the original Navashino design, making a complete analogue, but from laminated chipboard. But the design, as I already mentioned, suffered from a number of congenital defects, due to which, even without any increased loads ;-) the bed became loose very quickly.

In addition, the mattress also needed replacing - and I wanted to buy a new one 5 cm longer...

I Googled in thought...

And suddenly I googled this wonderful topic on the Guns forum

There, a comrade under the nickname Serjant told in detail and with photographs how he constructed a bed from wooden window sills and tabletops%) (We were talking about laminated wooden panels).

AND THE IDEA began to take shape: I would have a bed not made of pop laminated chipboard, but from natural wood 8-)

I’ll make a reservation here right away, because among my friends there are people who are on friendly terms with natural wood: for me, this was generally the first experience of making such a large-scale wooden product. I don’t take into account all sorts of small crafts, parcel boxes and a shelving unit in a barn (15 50*40 bars, two dozen “half-wood” joints)... I also don’t take into account laminated chipboard cabinet construction, because this is generally a “constructor” in which the main thing is - just draw it out correctly and drill it accurately. So, to be honest, I’m surprised that everything worked out almost as planned the first time. Not without its flaws, of course, but that’s why we are the Kosyakov plant ;-))))

Based on the experience of Comrade Sergeant, I began to figure out my project. First of all, I was interested in the availability of the material. Unfortunately, in our city I “offhand” did not find any offices that easily sold various types of glued window sills and tabletops. But I found out that in a large OBI anthill they sell so-called. “furniture panels” are the same glued wooden sheets of different sizes and thicknesses.

Great! There is a fundamental possibility. Let's take AutoCAD and start engineering =)

Unlike Comrade Sergeant, I needed a simple, bachelor, single bed. :-) However, the design as a whole was planned to be similar. What attracted me most about it was the idea of resting the longitudinal sidewalls (“strings”) on the grooves in the legs. As a result, weight is transferred not through screws or bolts, but directly from part to part.

But here I made one adjustment, directly in line with the old joke:

"a potty for a small apartment should have a handle inside, not outside" ;-)

Sergeant’s legs, as you can see, “stick out”:

And I decided to hide them inside the bed, because my room is small. :-))

So, we design the following two U-shaped frames:

For the mutual connection of the frames and headboards of the bed, comrade. The sergeant used numerous corners of his own production.

I decided to use parts from an old bed for this purpose. Perhaps the only good thing about it was these thermonuclear steel corners:

(yes, I’ll make a reservation right away - the photographs here and further do not shine with quality - because the photography was carried out in the process of hectic activity, only for the purpose of photographic recording - so there will be no high artistry %))

This is how they will attach the backs:

Now let’s design a support for the mattress - bars and a crossbar (I love such stiffening ribs - for the best %))

We place sheets of plywood on the bars like this:

And they have a mattress on them!

Once again I will focus on the design of the legs:

The string rests directly on the stem, and the corners only connect the string to the backs.

Why should we build a house... 8-)

Now it’s a matter of embodiment in the material.

To make strings at OBI I found a furniture panel measuring 400*2400, thickness 20. Made of pine. I agree, pine is not the best material for furniture. But besides pine there was only oak... at prices that negated the entire economic part of the project%)

Well, pine is easy to process and light - and my whole room is

light colors.

The situation with the backs was more complicated - there was no suitable shield at that moment. But, having wandered around the “wooden row”, I discovered a piece of material that was remarkably suitable for my purposes.

The glued slab, all made from the same pine, with dimensions of 900*900 and a thickness of 40, was called... “Staircase landing” ;-)

Well, I'll sleep on the landing! :-)

Since you’re going to buy material from OBI, it’s not a sin to use their cutting service.

The long shield was cut in half lengthwise, and a piece 400 long was cut from each of the resulting boards - we got blanks for strings and legs. I cut the “staircase landing” into two parts, 350*900 and 550*900 - the blanks for the backs came out.

stra_nn_ik helped deliver all this lumber to the house on his Niva, for which he received separate tanks: -)

stra_nn_ik helped deliver all this lumber to the house on his Niva, for which he received separate tanks: -)

All further action took place on the floor, in the living room, in fits and starts in the evenings and weekends. I was in no particular hurry, and there was a lot to do besides this work - as a result, the bed began to take shape only after a month. I would also like to note that if I had at least a simple workbench and a room where I didn’t have to worry about collecting dust and covering the floor with shavings, everything could be done better and faster. Well, in my case, the bed turned out to be made on the knee in the literal sense.

However, let's move on to the photo narration. ;-)

We will make legs from these pieces:

By sawing both in half lengthwise, we get four blanks.

Next, in each we make a sample approximately 8 mm deep using a chisel.

In terms of height, the calculation is such that there is 150 mm between the lower edge of the string and the floor. This is due to the size of a couple of boxes with all sorts of useful hardware that live under my bed =)

The blanks for the strings are lightly cut to the exact length (mattress length 195 + 10 mm play on each side) and places for attaching the legs are marked on them.

The process is controlled by Comrade Stepan (in civilian clothes, from the military acceptance area, of course ;-) )

This is how we firmly attach the legs to the strings.

For glue, + 13 screws (favorite number%)) + one bolt (the latter is more likely “for the best” and for some design reasons - well, I like bolts! ;-) And it turned out to be very convenient for preliminary assembly).

Please note that the corners initially had only two holes for screws on each side. For the old bed, bolts were the main fastening element. And it wasn't very good. I corrected the situation by drilling more holes in the corners - as a result, 6 out of 13 screws secure not only the leg itself to the string, but also the corner to the entire structure.

Next, I bought two bars with a cross section of 40*30 and a length of 2 meters. I sawed them, getting two long support bars and two shorter ones. In the long ones I made a chisel sample for the future stiffener:

And he attached these bars to the strings with glue and screws:

Now we take the former staircase landing (future backrests) and drill holes for the bolts.

Hooray! You can do a test build!

Stepan controls the strength of the structure ;-)

We also attach support bars for the mattress to both backrests.

But then an ambush arose. During the test assembly, it turned out that the “high” back, taking into account the thickness of the mattress, is not high enough (sorry, there is no photo for illustration).

And it was decided to introduce a certain revitalizing note into the brutal cubism of the design)

I went to the dreamy store “Young Technician” (fortunately, I live nearby) and chose a 35*40 block with the most pronounced wood texture.

True, it was not planed. I had to use a beast-machine, an electric planer!

Here's how nice it turned out:

(By the way, for processing, the block is attached to a part from an old bed. You can see some continuity in the design ;-) )

We mark the resulting block...

And now your word, Comrade Forstner! (by the way, he was a gunsmith)

We drill similar holes with a diameter of 20 and a depth of 15 at the end of the back.

In this photograph, the face of a drummer from a bed-building workshop is set on fire. :-)))

[img]https://cn1.nevsedoma.com.ua/images/2010/41/4/8

3287246.jpg[/img]

From the same OBI, we purchase a rounded strip with a diameter of 20, and cut it into posts with a height of 110.

These are the “towns” we got ;-)

Well, now the logical conclusion - insert - time!

We hope - two!

It turns out to be such a cool picket fence :-)))

We assemble it all with wood glue.

While it’s drying, let’s put a decorative gloss on the strings, remove the beast-machine, and use an electric plane to create an even chamfer:

In addition, the corners of the backs were cut off on the underside to form a plinth so that the bed could be placed along the wall.

So, all the main details are ready.

Then I sanded all the parts manually (because I haven’t acquired a sander yet %)). Luckily for me, the source material is sold already sanded - so it was more likely to just add some polish and remove traces of markings.

Well, then I covered all the parts with colorless furniture varnish (I took the first one that came to hand, the one from Yaroslavl - and it turned out to be a very good varnish).

The inner part of the strings was covered once, and not sanded, but the outer surface, as well as the backs, was covered in two layers, with sanding in between.

When the varnish had dried thoroughly, based on the experience of Comrade Sergeant, I made pads for the legs from a simple thick insole :-)

Well, everything is ready for the final assembly!

Bolted, drilled and screwed!

“To make it better,” I added additional small corners at the bottom of the legs.

Bah! It looks like it turned out just right! :-)

We fasten the crossbar - also a shield purchased from OBI, 200*1000, thickness 18. I just sawed it off to the width of the bed (810), did not varnish it.

For now, I also borrowed sheets for the mattress from an old bed - fiberboard 8 mm thick. But I plan to replace it with plywood in the near future, so that everything is fresh and new.

Well, now - a mattress!

All! The object is ready.

Stepan sniffed everything meticulously and checked it. I was quite pleased. :-)

I'm also quite pleased with how it turned out. Considering that this is my first experience in making a bed... :-)

Yes, I completely forgot to announce the budget: it took me a little more than 3 thousand rubles to purchase all the materials. ;-)

bu33er