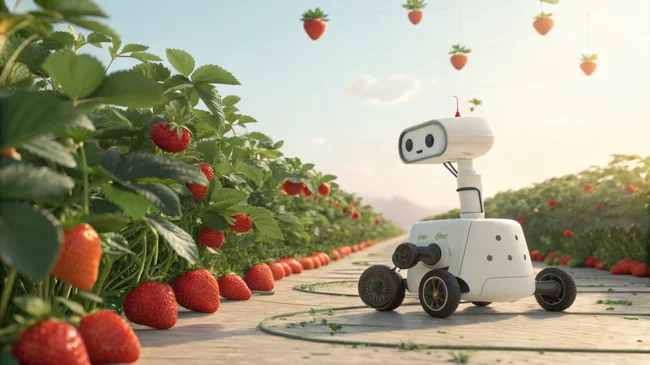

A large robotic greenhouse (3 photos + 1 video)

A company known for home appliances has created a huge robotic greenhouse where strawberries grow all year round under the control of artificial intelligence.

A farm of the future has appeared in Britain, or a rotating, smart and almost autonomous structure, where it is dangerous to go hungry. Inside the greenhouse, berries grow in motion, and the microclimate is adjusted automatically. LED lamps illuminate the beds, and robotic blades water them with collected rainwater.

Dyson, a company known for its engineering solutions, has presented something unexpected - a huge installation for year-round cultivation of strawberries. The new product is located in a glass greenhouse near Lincolnshire in the eastern part of England and looks like a rotating wheel with containers where berries grow. The design allows to provide the plants with uniform light and fresh air. Each bush slowly moves in a circle, falling under the lamps and ventilation.

The 26-acre greenhouse contains over a million seedlings. The yield is off the charts - up to 1,250 tons per year. The conditions are regulated automatically: temperature, humidity, carbon dioxide and the amount of water are always under control so that the fruit plants do not dry out. Rainwater is used, which is collected and recycled to be put back into use. The roots do not suffer from excess liquid, because the drainage system protects the plants from over-watering.

All processes inside are controlled by a computer system

Sensors monitor the condition inside the device, and robots with cameras and manipulators are responsible for collecting readings. They carefully separate ripe fruits without damaging the bushes. LEDs replace the sun on cloudy days, and ultraviolet lamps protect Victoria from fungi. To combat pests, farmers decided to abandon chemicals. Instead, researchers launched biological assistants - special insects that are distributed among the beds by small mechanisms.

There is a bioenergy complex next to the greenhouse. It converts agricultural waste into electricity and heat, which power the entire system. Carbon dioxide is also used - it is sent back to the greenhouse, where it accelerates plant growth. The remaining sludge after processing is converted into fertilizer for other fields.

The energy obtained powers the greenhouse, and the remainder is used for organic fertilizer.

Thanks to the system, the load on the land is reduced, and resources are conserved, so the harm to the environment is minimal. The model works in any weather conditions and is suitable even for those regions where traditional agriculture is impossible due to a short season or poor soil. The approach can be tested on other crops.

Dyson promotes the idea that fruits and vegetables can be grown within the city, right next to stores or in former industrial zones. This will reduce transportation costs, preserve the freshness of organic products and reduce emissions into the atmosphere.

The project was implemented as a result of several years of painstaking development. It combines advanced technologies and sustainable production, opening a new page in the agricultural industry. Dyson shows how you can change the idea of farming, making it highly precise, environmentally friendly and independent of the climate.