Brembo and Michelin are working on adaptive brakes (3 photos)

"Smarter" calipers and tires packed with sensors will be able to stop the car in the best possible way.

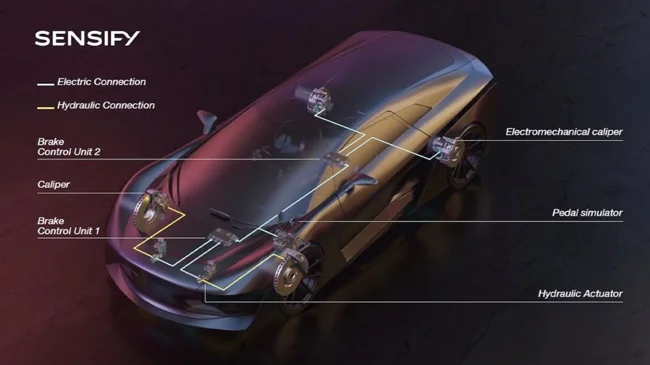

A leading manufacturer of braking systems and one of the global leaders in the rubber industry have collaborated to create a new generation of Brembo Sensify brakes, which are devoid of a direct physical connection between the pedal and the mechanisms.

The system uses the brake pedal to send a signal to the electronic control unit, which is responsible for distributing the braking force to each of the wheels. The pads are activated either hydraulically, where each caliper has its own master cylinder with an electric drive, or using only electric motors that actuate the pads without any liquid.

Both brake systems can be combined. For example, hydraulic with electric drive for the front wheels and fully electric for the rear.

In turn, the operation of the control unit software takes into account the information collected from sensors inside the tires in real time, namely the degree of load on the tire, its wear level, internal pressure and temperature of the rubber layer. Using these parameters, the coefficient of adhesion is calculated, which is crucial for any braking system.

When driving, Sensify distributes the braking force, assessing everything that affects the tires and braking efficiency, and then makes adjustments on the fly, which is especially important for the operation of ABS.

Following the computer simulation phase, physical tests involving full stops at speeds between 50 and 138 km/h began at the Michelin proving grounds in autumn 2024. The tests are carried out in dry and wet conditions, on cars with both summer and winter tires, new and worn, inflated to the standard and below it.

In terms of vehicle dynamics, the goal was to maximize tire grip in all scenarios. So far, the testers have reportedly managed to reduce the braking distance by up to 4 meters compared to a car with “standard” ABS.