Scientists have come up with a way to make soap from plastic (4 photos)

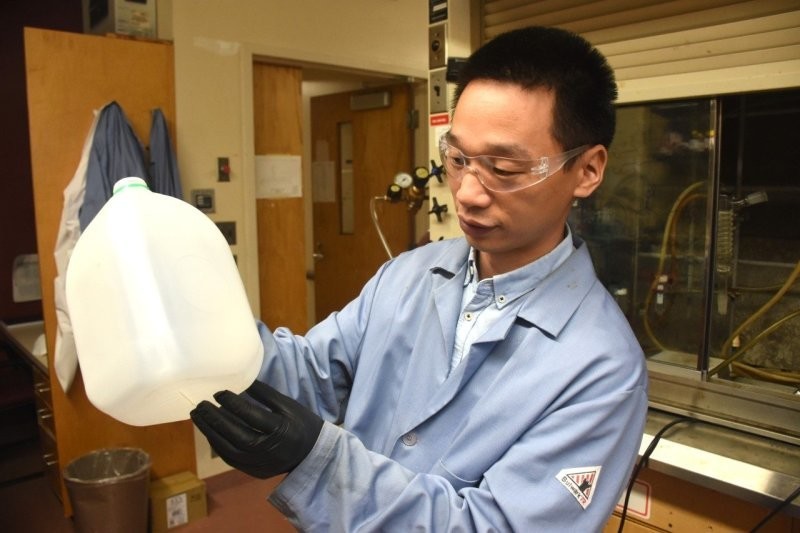

Chemists at the Virginia Institute of Technology (USA) developed an innovative recycling method: plastic waste becomes a raw material for the manufacture of soap and other detergents.

Researchers - Guoliang Liu and his colleagues - discovered new method of processing plastics into soap. Method: heat long carbon chains in plastic, then cool them quickly.

Guoliang Liu

The problem of pollution of the planet with plastic waste is worth extremely acute, and scientists are trying to find a solution to it. Recycle plastic in plastic is unprofitable, since you can only get the worst material quality. But it turns out that plastic can be recycled into surface-active substances (surfactants) necessary for the manufacture of soap and other detergents.

This option is possible due to the fact that the chemical The structure of polyethylene is in many ways similar to that of a fatty acid, one of the components of the soap. Fatty acid, like polyethylene, contains long carbon chains, with only an extra group of atoms.

Guoliang Lui and colleague Eric Munanese experiment with plastic recycling

Guoliang Liu figured out that polyethylene can be turned into fatty acids, which then become components of soap solutions. By According to him, the decision came to him unexpectedly. He watched how a fire is burning in the fireplace, and I thought that when the wood was burning in The smoke emitted contains small particles of wood. Polymers break down into separate particles in the form of chains, which later become carbon dioxide and are completely decomposed.

Could similar processes occur with plastic? The scientist understood: in order to get such a “smoke” from plastic (before it burns out completely), break long polymer chains into short and convert polyethylene into fatty acids, a special oven is needed, or reactor.

The waxy substance obtained from the reactor is heated to oil bath, and paraffins are oxidized by air flow to form fatty acids by catalytic oxidation

In this reactor, high temperatures are maintained at the bottom, so that the polymer chains can be broken, and the top is cooled to could stop their further destruction.

The output is a waxy substance that can be convert to fatty acids. The method works well with basic types plastic - polyethylene and propylene. It is economical (you only need heat and plastic) and can be cost effective.