Ingenious way to replace old sewer pipes with new ones (6 photos)

Replacing old sewer pipes can turn into quite an adventure. Getting to the latter can be difficult, because such a procedure is carried out very rarely. However, time spares no one and nothing, be it super-modern plastic or trusty steel. Sooner or later, the rehabilitation of water supply communications will have to be carried out anyway.

Fortunately, today there are technologies for this that allow you to do without excavation at all.

The average service life of steel water pipes is 15 years. If they are made of galvanized steel, then the average service life is doubled. However, much also depends on the quality of the pipes and the specific grade of steel. The installation method used has a serious impact. Welded structures naturally serve much less than all-metal ones.

In addition to steel pipes, copper and polymer pipes are also widely used in plumbing. The latter last the longest. The average service life of polypropylene communications reaches 50 years. However, even they “do not last forever under the moon”. This means that sooner or later the sewer pipes will have to be replaced.

Needless to say, in most situations, replacing sewer pipes is a real challenge. Fortunately, today there are installation technologies that allow you to replace communications with minimal opening of pipes or without it at all. This technology is called "Relining". The name comes from the English word "Relining", which is translated only as "Repeated laying". And it should be noted that this is one of those cases when the name of the procedure says practically nothing about the method and mechanics of the rehabilitation. Moreover, today there are several methods of "relining" sewers. However, the so-called stocking method remains the most popular.

The "stocking" method is a method of re-laying sewer pipes using a special polymer sleeve. Pipe rehabilitation consists of several stages. First, the pipeline is prepared: installers conduct a television inspection, based on the results of which a decision is made on the need and method of cleaning.

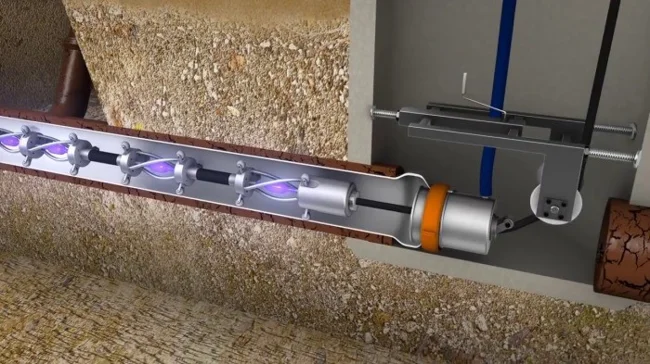

Most often, a regular hydrodynamic flush of the sewer pipe is sufficient. After this, workers move on to the second stage - pulling a flexible composite sleeve made of polyethylene film through the pipe. At the time of pulling, both ends of this sleeve are closed with special plugs-packers, each of which is equipped with an air branch.

As you can easily guess from the latter, the polymer sleeve is stretched along the sewer pipe by "blowing" with an air compressor. Thanks to its work, the polyethylene film adheres to the walls of the water pipe, thereby taking the shape of the pipe being sanitized. In other words, the "stocking" creates a new plastic pipe inside the old metal one.

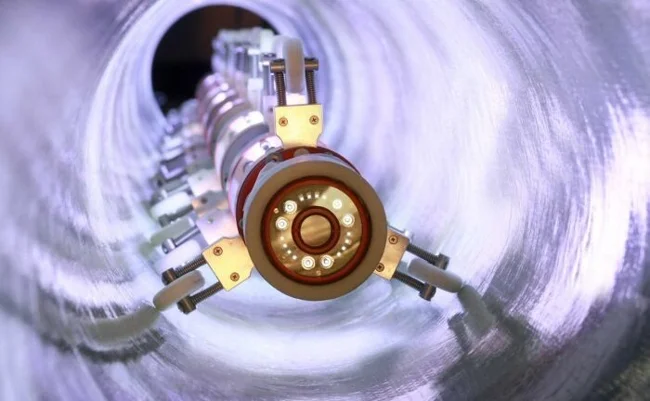

The "blowing" process is constantly monitored using special equipment equipped with surveillance cameras. After stretching the sleeve, ultraviolet emitters are launched into the pipe. The impact of the latter leads to the polyethylene film hardening, thereby turning into a full-fledged fiberglass sewer pipe. After this, the workers only have to wait a little and carry out an inspection to control the quality of the work done.