Classic internal combustion engines (ICE) have not changed fundamentally over the century and a half of their existence. The design of the crank-connecting rod ICE has been perfected by generations of engineers: these are cylinders with valves, pistons, connecting rods, shafts...

Designers never stopped thinking: how to do without pistons, connecting rods, valves and other parts moving back and forth?

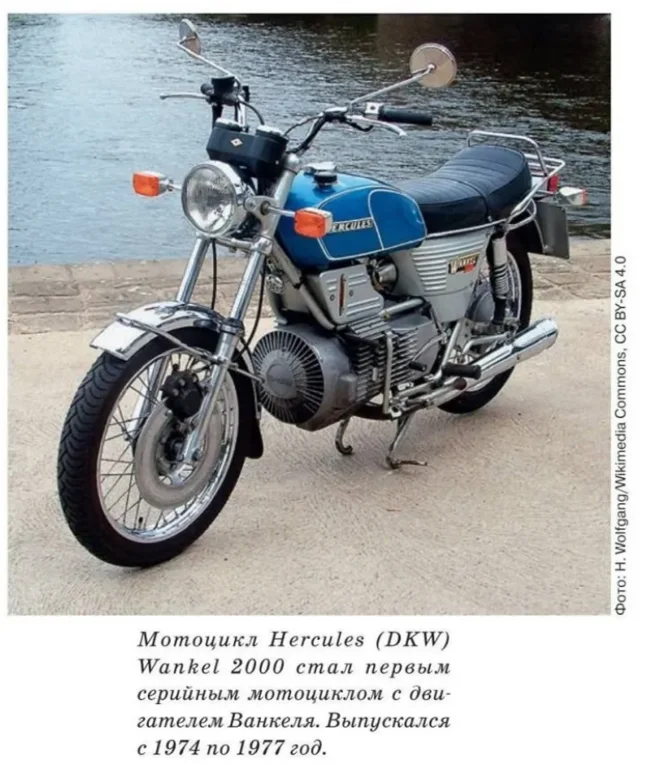

The solution was a rotary piston engine. Many different rotary engines have been proposed, but only one has reached serial production so far. In 1957, designers Felix Heinrich Wankel, Walter Freude and Hans-Dieter Paschke, who worked at the German automobile plant NSU (Neckar Sulm Union) Motorenwerke, patented an engine that is now known throughout the world as the Wankel engine, rotary piston engine (RPE), rotary engine or simply "Wankel". At first, it was called in German modestly and not very clearly - "Kreiskolbenmotor", which literally means "circular piston engine".

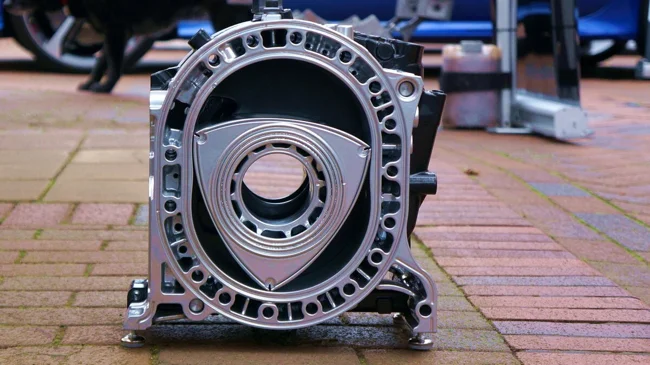

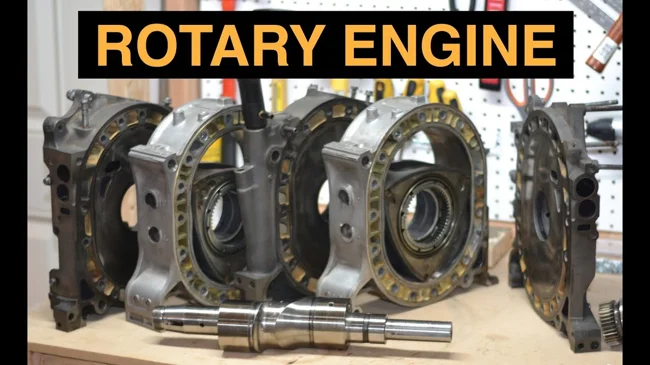

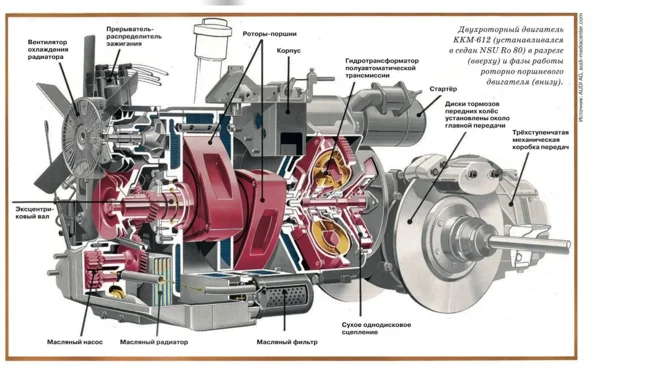

A rotary engine, in its simplest form, consists of only three main parts - a housing, a rotor, and a shaft. The RPD turned out to be very light and one and a half to two times more compact than its piston relative, it has about a third fewer parts. The rotor and eccentric shaft rotate uniformly, without stopping, accelerating or decelerating, so the rotation speed can be increased by 2000-3000 rpm, which gives a higher specific power. Friction losses are small, mechanical efficiency is high. If desired, six or even more rotors can be arranged one after another on a common eccentric shaft. Such an engine will be called multi-section or multi-rotor. It is impossible to do this with a piston ICE.

Problems with RPDs begin when it comes to efficiency, resource and environmental friendliness

· The design of the rotary engine causes high fuel consumption and insufficient environmental friendliness compared to piston engines. This is because during the operation of a high-speed rotary engine, the fuel often does not have time to burn completely.

· A rotary engine also means significant oil consumption. To lubricate the seals, a certain amount of engine oil enters the working cavity and mixes with the fuel-air mixture, burning together with it.

· Rotary engines are prone to overheating - they heat up much more strongly and unevenly compared to piston engines.

But all these problems seemed insignificant, and then, in the late 1950s, the appearance of the "miracle engine" caused a real rotary boom. The compactness, efficiency and simplicity of the new engine conquered everyone, and toxicity and fuel consumption were not yet given much attention. "It's as simple as an electric motor!" exclaimed enthusiastic enthusiasts. It was believed that the days of classic piston engines were numbered, even trucks and diesel locomotives would soon have a rotor and only it!

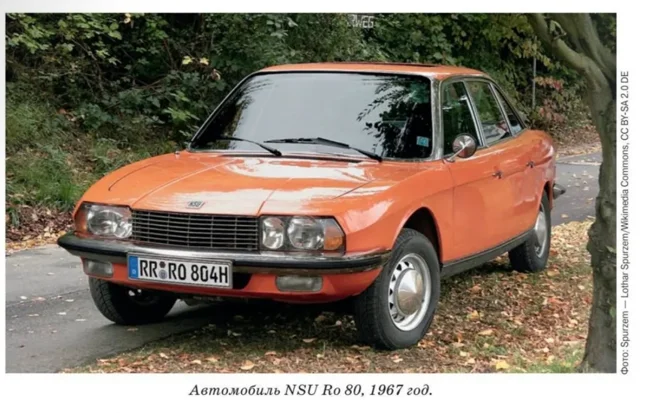

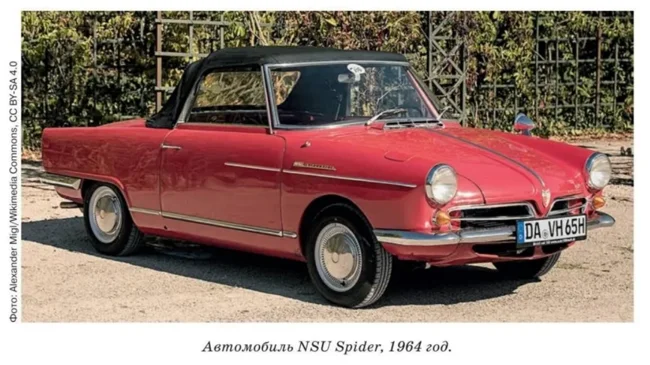

Already in 1963, the NSU plant produces the world's first single-rotor rear-engine two-seater coupe-roadster NSU Spider, and four years later the full-size elegant sedan NSU Ro 80 with a two-rotor KKM-612 engine appears.

The volume of this engine was slightly less than one liter - only 995 cubic centimeters, but it produced a power of 115 hp. s., while the usual four-cylinder engine of that time

with a volume of 1.6 liters developed on average no more than 80 hp. The car immediately won the title of "Car of 1968". But when the fireworks died down, it turned out that the engine was only enough for 30-40 thousand km

of mileage. The world's auto-moto giants gradually and quietly began to abandon the unusual engine, which deceived their expectations.

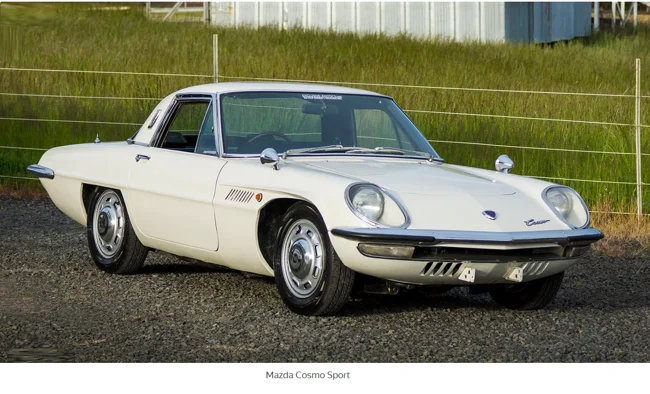

All, except for the Japanese Mazda Motor! For almost half a century of hard work, a group of engineers led by Takashi Yamaguchi has practically managed to minimize the shortcomings of the first generation rotary engines.

Mazda Engine

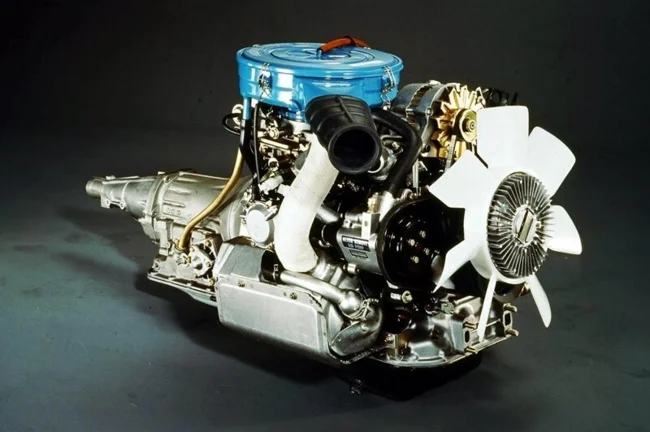

The success was facilitated by the use of microprocessor injection, dual ignition, variable valve timing with several intake ports in the covers, as well as the coating of the housing mirror and covers with porous chrome impregnated with Teflon. The steel rotor of the engine was as light as possible. A three-component thermal neutralizer burned unburned hydrocarbons

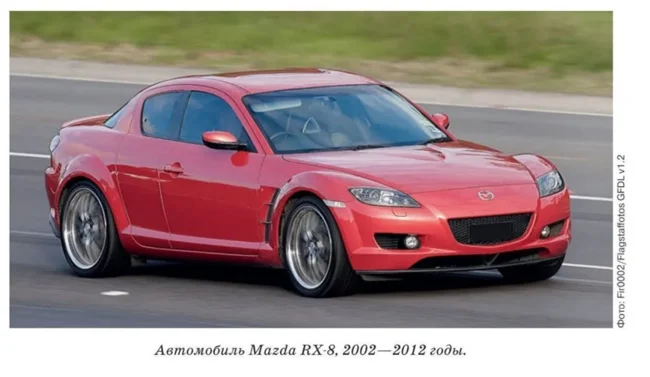

by adding clean air to the exhaust. Let's not forget that at the same time the quality of the fuel improved and ash-free oils appeared that do not form solid abrasive particles during combustion. The two-rotor 13B-MSP Renesis engine of the Mazda RX-8 (produced from 2002 to 2012), with a working volume of only 1308 cc and a weight of 122 kg, developed, depending on the modification, a power of 192 to 250 hp at 8500 rpm. In 2003, Renesis was recognized as

"Engine of the Year" at the International Engine exhibition. The toxicity of the engine emissions complied with Euro-IV standards (by the way, it was the fact that Renesis could not reach the stricter Euro-V standards that caused its production to cease). The service life, with responsible attitude and proper maintenance, was almost as good as the service life of a piston engine of a similar volume. From 1967 to 2012, Mazda Motor Company produced 1.9 million cars with rotary engines.

The fate of the Wankel engine was very difficult. Interest in it flares up at a new stage of development of materials and technologies, then fades away again. Does this idea have a future?

Add your comment

You might be interested in: