The Internet showed step by step how instant noodles are made at a factory in South Korea (21 photos + video)

We once made an interesting post in which we showed how Crab sticks are made in a factory in Thailand. And now the time has come for another product that is hard to imagine without modern world. We are, of course, talking about instant noodles. We invite you to look at the interesting step-by-step cooking process ramen at a Korean noodle factory.

And before that, let’s take a small lyrical digression. Can talk as much as you want about the uselessness of "doshik", but sometimes it really helps out a lot. And I must say thank you to Momofuku Ando. This Japanese invented instant noodles back in 1958. He named his the creation is simply "Chikin Ramen" (the name comes from the traditional noodle and chicken based dishes).

To say that noodles changed the game is an understatement. More In addition, in 2020, Japan named instant noodles its the main invention of the twentieth century.

Well, now let's see how ramen is created in a Korean factory.

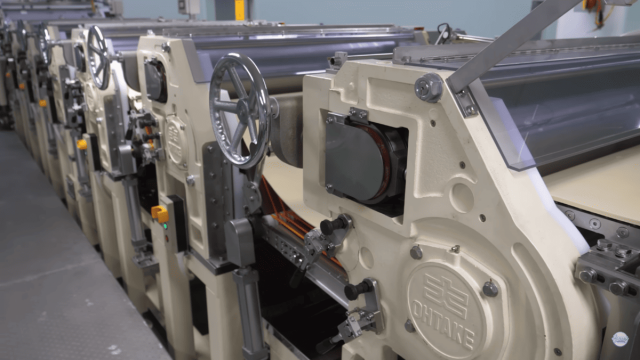

All the magic of making instant noodles starts here:

Natural chicken broth is poured into the tank with saline solution

The liquid is thoroughly mixed until the ingredients are completely combined

Next, in the mixer, the chicken brine is combined with premium flour

The finished dough is sent to the ripening chamber

After a certain period of time, the percentage of moisture in the dough is measured.

By the way, the dough has a non-uniform texture and looks crumbly. But its structure is of the correct density and ductility so that When rolling, the integrity of the canvas was maintained.

The finished dough arrives for sheeting

At the beginning of the process the thickness of the dough is approximately 1 cm

But after multi-stage rolling under rollers and presses, it becomes only about 1 mm thick.

After rolling out, the dough goes to the longitudinal cutting unit

And now we will reveal the secret of the century: how are noodles made? curls? In fact, everything is much simpler than it seems. In progress While slicing, one of the blades moves slightly slower than the other. Because of this the noodles seem to be crushed, forming a wavy mass.

By the way, this noodle shape was invented for a reason.

The noodles are given such a recognizable shape specifically to make them easier to brew and eat.

The chopped noodles are sent to the pressure chamber for steaming until fully cooked.

Next, the steamed noodles are placed in molds

Water again with saline solution

And sent for deep frying

Frying in oil is one of the key aspects of production

Thanks to frying, the noodles acquire a porous structure, which is makes it so quick to prepare. Hot water steams the noodles from the inside, increasing its volume and making it softer.

On the conveyor belt, the noodles undergo standard and quality control

Using metal weights, excess noodles are removed, knocked out of the briquette. This helps the finished product to have perfect form.

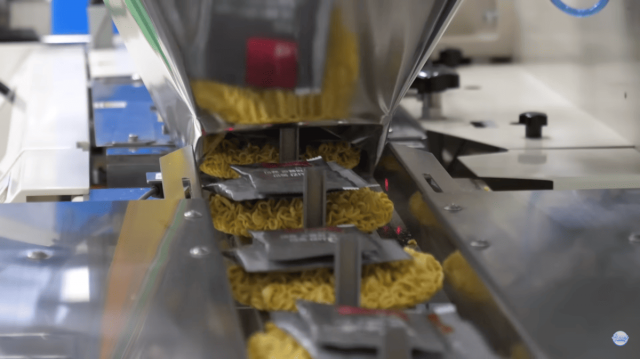

After all manipulations, the noodles enter the packaging workshop

Here they collect the full set: noodles, broth, dried vegetables. What typical for a particular production - meat broth is boiled from natural bones, fresh vegetables are sublimated directly at the factory, and meat The sauce is made from natural meat. Of course, different productions differ: some use more chemical seasonings, others strive for natural production as much as possible.

The formed set is sent to the packaging belt

This is where the finished product is packaged

Which is then sent to store shelves

Dinner is served!